Welcome to the Digital Age

Quality Discount is proud to partner with both LEMORAU and INX to distribute and support their Digital Printing Presses. Please contact us for more information at digital@qualitydiscount.com or give us a call! We would love to hear from you.

INX NW340 WEB PRINTER

UV DIGITAL LABEL PRODUCTION SYSTEM

• Digital Production for Label Printing

• Integrated Laser Cutting Station

• Best in Class Performance & Image Quality

• UV LED Cure Technology

• FujiFilm Samba® Printhead Technology

• From Design to Labels in Minutes

• Up to 100 meters per minute

• Variable Image and Variable Cut

• Inline Finishing Options for One Step Production

• 340mm Printing Width

• Modular and Expandable

The NW340 Web Printer enables label converters, packaging, in-house and commercial printers to evolve to digital inkjet technology. This complete solution includes high quality inks and modules that help printers meet the growing demand for high quality, productive short-run digital printing.

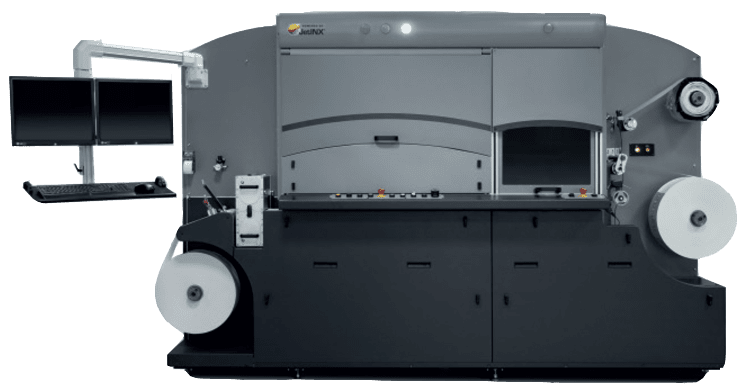

INX NW140-E / NW210-E

LABEL INTENSIVE THINKING

ADVANCED DIGITAL TECHNOLOGY FOR NARROW WEB PRINTING

Delivering single pass output up to 80 fpm on any label stock. Combines printing and conversion to produce vivid color printed labels at a maximum printing width of 210 mm/8.25 in. Comes equipped with a Spartanics laser die cutting station and Xaar patented technology, with multiple drop sizes and color ink channels.

1. Control Workstation

A powerful double-screen workstation allows the operator to easily check and manage every part of the system, from file upload and mechanical/laser settings to printheads and hydraulic adjustments.

2. Mounting Station

Once the new roll is fixed on unwinder, it’s easy to feed it using the bending knife and hook it up to the existing strip. Drive the web and tighten it through the whole path in just a few minutes.

3. Printing Unit

The beating heart of the NW140/E and NW210/E printers are their easily accessible printing tower, equipped with six stations (CMYK, White and optional Varnish) and a total of 12 Xaar 1002 industrial inkjet printheads, with a smallest droplet size of 6 picoliters.

4. Web Cleaning Unit Utilizes two groups of cleaning rollers combined with rubber rollers to remove dust and dirt. The two anti-static units remove any remaining electric charges.

5. Laser Die-Cutting

A fully-integrated end-to-end workflow is guaranteed by the in-line laser cutting unit. It allows the seamless production of any type of labels starting from digital design to finished product.

6. Heavy-duty rewinder

Finished labels, perfectly printed, cured and cut, are instantly rewound on a motorized roll. Through a quick and easy operation they can be removed, packed and made available for customer delivery and application.

7. Flood lamination unit

A high-speed cold-lamination unit is available for the flood (full coverage) lamination of any labels.

8. Corona station

A corona station is available on the NW Series for pre-treatment of substrates with low surface energy. Corona is recommended only

9. Variable data

Customers who need numbering, language versioning or fully-customized labels, even starting from a simple PDF or raster file, can count on the powerful variable-data features of NW Series.

10. Roll-to-sheet unit

A versatile cross-cutting unit is available for in-line cutting of customized from the printed reel. Easily switch from cut labels to direct-mailing and 1:1 marketing campaigns up to A4 and other sheet-sizes.

11. Semi-rotary die-cutting unit Optional / In place of laser die-cutting

A physical die-cutting unit is available for those customers who require the highest customization in terms of texts, colours, languages and quantities, but have standard label-sizes or limited die-cut changes over the year.

12. Brand protection capabilities

To help mitigate counterfeiting, maintain product and supply chain integrity, covert Track and Trace formulas are available that enables product authentication and verification as well as location services.

LEMORAU EBRM+

ROTARY / SEMI-ROTARY TABLE TOP FINISHING MACHINE

Lemorau EBRM+ is an affordable table top digital finishing machine that can coat, die cut, slit, and rewind digtial printed webs. Due to an electronic feeder roll, the machine can be used as in-line finishing machine together with digital press or as offline finishing machine. The ERBM+ die cutting unit can run in full and semi-rotary modes. The web tension control is electronically controlled and due to the machine mechanical shafts no air is required.

Standard Features

- Maximum rotary speed 80 m/min. (262.4 ft / min.) – Die cutting to register

- Maximum semi-rotary speed 25 m / min (82 ft / min.) dependent on plate size – Die cutting to register

- Web width 250, 330 mm (10, 13 in)

- Electronic labels and meters counter

- Web guide with splice table

- Variable web tension control (automatic on unwinder, rewinder, and waste rewinder)

- 6 sets of circular knives with lateral adjustment

- 1 rewinder mechanical shaft with max. diamter 360 mm (14 in)

- 1 waste rewinder mechanical shaft with max. diameter 360mm (14 in)

- 1 lineless lamination unwinder mechanical shaft with max. diameter 300 mm (12 in)

- Labels in/ Labels out rewinding

- Die cutting unit in register with rotary / semi-rotary modes and lateral adjustment

- Standard gears for magnetic cylinders are 1/8 CP, straight teeth, angle 20 degrees

- Semi-rotary magnetic cylinder Z130

- Die repeats 20,320 – 43,180 mm (8 – 17 in) – Rotary mode

- Recommended die repeat 8,255 – 33,020 mm (3.25 – 13 in) – Semi-Rotary mode (Z130)

- Electronic sensors to start, stop, move faster and move slower

- Color touch screen with multi language function

- Remote assistance through internet connection

- CE conformity certificated, user manual and electrical scheme

Optional

- Additional slitting knives

- Anvil roll with adjustable gap

- Clear on clear sensor

- Digital printing unit to work in-line -> DIGI LC

- Infeed tension system to work inline w. flatbed, semi-rotary and screen machines

- Right to left configuration

- Pnuematic air shafts

- QRC (Quick Remote Connection)

- Razor slitting knives

- Rotary / semi-rotary UV Flexo

- Unwinders for offline mode with max. diameter 360mm (14 in)

- Work bench